Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- References

- Copyright

Performance Analysis of an Asphalt Mix

Authors: More Harish Shantaram, Fulpagare Kapil Ratilal, Ratnaparkhi Bhavesh Kiran, Kadhre Pratham Bhalchandra, Prof. P. R. Badgujar, Prof. S. Y. Sonawane, Prof. J. P. Bhadane, Prof. N. R. Borase

DOI Link: https://doi.org/10.22214/ijraset.2024.65067

Certificate: View Certificate

Abstract

This study investigates the performance characteristics of asphalt mixes used in roadway construction, focusing on their durability, resistance to deformation, and overall mechanical properties The concentration of bitumen in a Marshall mix sample significantly impacts the performance and durability of the asphalt mixture. Bitumen, also known as asphalt binder or asphalt cement, is a binding agent that holds mineral aggregate together. The optimum bitumen content is typically 4-6% by weight, with a 5% concentration resulting in a strong, durable mix with good workability, compatibility, resistance to rutting and fatigue cracking, and resistance to moisture damage and environmental stresses. Higher Marshall Stability values indicate stronger asphalt mix, while higher CBR values indicate stronger subgrade or base material. Both factors ensure road structure strength and stability.

Introduction

I. INTRODUCTION

The introduction explains the importance of high-performance asphalt mixes in modern infrastructure. High-quality asphalt pavements are essential for reducing maintenance costs and ensuring road safety. The purpose of this research is to analyze the performance of asphalt mixes under various conditions, specifically targeting performance metrics like stability, deformation resistance, and durability. Additionally, the study addresses how factors like aggregate composition, binder properties, and additives impact the performance of asphalt mixtures.

II. OBJECTIVES

- To evaluate the impact of aggregate gradation and binder content on asphalt mix performance.

- To assess the effects of different additives on asphalt durability and rutting resistance.

- To analyze the relationship between asphalt mix properties and performance in varying climates.

III. LITERATURE REVIEW

Jitsangiam et al., 2023 The environmental issue of plastic waste and proposes a modified mix design framework for hot-mix asphalt concrete (ACP) that incorporates recycled plastic. The study introduces the concept of dry mixing, where plastic is directly mixed with the hot aggregate, and evaluates the performance of ACP compared to conventional asphalt concrete (AC) through laboratory tests. The results indicate that ACP exhibits superior performance, highlighting its potential as an alternative solution for recycling plastic waste in road construction.

Oreskovic et al., 2023 This study investigates the feasibility of incorporating copper slag (CS) into asphalt mixtures for both the surface and base layers of road pavements. Two sets of asphalt mixtures with different CS content and fraction sizes were prepared, and their performance was evaluated. The results showed that adding CS to the surface layer improved stiffness and rutting resistance without significant negative impacts on other properties, while adding CS to the base layer improved cracking resistance but negatively affected stiffness, rutting, and fatigue resistance. Overall, CS has the potential to be a suitable substitute for virgin aggregates in asphalt mixtures for both surface and base layers.

Rivera et al., 2023 The use of polymer-based household waste in the wearing course of flexible pavements has been analysed, either as an asphalt bitumen modifier or as a dry additive. However, there are not enough records in which this waste is used to make up the aggregate to be used in an asphalt mix. This article presents the development carried out at LEMaC, consisting of pieces made from the mixture of household waste polymers and soils, which has been called Polymeric Stone. This material is used to design a cold-mix asphalt, and its use has been validated after evaluating a series of properties.

Khan et al., 2023 This research evaluated the use of marble dust (MD) as a substitute for mineral filler in hot mixed asphalt (HMA).

The Marshall stability test results showed that an optimum filler content of 4% MD improved the Marshall stability, rutting resistance, and permanent deformation of the asphalt mixtures, while reducing the fatigue life. Increasing the percentage of MD increased rutting resistance and stiffness at high temperatures, but decreased the fatigue life. MD can be used as a partial substitute for stone dust (SD) to enhance rut resistance in HMA mixtures, particularly in areas with significant MD waste.

Upadhya et al., 2023 In this study, the researchers aimed to find the most suitable prediction model for Marshall Stability and Bitumen Content in carbon fiber reinforced asphalt concrete for flexible pavements. They used Marshall Stability tests and considered published research articles to analyze and select the optimal model. By applying various input parameters and machine learning techniques, they found that the Random Forest-based model performed the best, with high accuracy and low error metrics, indicating that a binder content of approximately 5.0% significantly influences the Marshall Stability in carbon fiber-reinforced asphalt mixes.

Ozel et al., 2023 This study examined the potential use of olive pomace (OP) waste, a type of biomass waste, in modifying bitumen for asphalt. The performance and cost of OP-modified bitumen were compared to styrene butadiene styrene (SBS) modified bitumen, commonly used in asphalt modification. The results showed that OP-modified bitumen, particularly with a 19% OP addition, exhibited similar performance to 4% SBS modified bitumen, improving properties such as rutting resistance, fatigue, and thermal crack resistance. This suggests that OP can be a viable alternative to SBS in terms of performance and cost, while also reducing environmental damage caused by waste materials.

Naser at al., 2022 This research evaluated the performance of hot mix asphalt (HMA) mixes with recycled asphalt pavement (RAP) and recycled concrete aggregate (RCA) as replacements for natural aggregate in flexible pavement surface layers. The study involved two phases, investigating different aggregate materials and studying the replacement of crushed limestone with RAP and RCA at varying asphalt cement contents. The experimental results showed that using RCA violated air voids limits and increased the optimum asphalt content, while adding RAP improved the Marshall stability of the HMA mixes.

IV. METHODOLOGY

This section details the experimental setup and tests used in the study.

A. Materials

The Asphalt mixtures used in this study contain various types of aggregates and binder contents. Additives such as polymers and fibers are also incorporated to enhance performance.

Materials required for preparation of Asphalt mix

Aggregate-

1) Tests on Aggregates

- Impact Test [IS Code 2386 (Part IV) – 1963]

- Crushing Test [IS Code 2386 (Part IV) – 1963]

- Abrasion Test [IS Code 2386 (Part IV) – 1963]

- Soundness Test [IS Code 2386 (Part V) – 1963]

- Shape Test (Elongation & Flakiness Index) [IS Code 2386 (Part I) – 1963]

- Specific Gravity and Water Absorption Test [IS Code 2386 (Part III) – 1963]

2) Tests on Bitumen

- Penetration test [IS Code 1203– 1978]

- Ductility test [IS Code 208– 1978]

- Softening point test [IS Code 1205]

- Specific gravity test [IS Code 1202– 1978]

- Flash and Fire point test [IS Code 1209 – 1978]

- Bitumen Adhesion Test [IS Code 6241 (Part IV) – 1971]

V. RESULT AND DISCUSSION

TABLE 1

VALUES OF AGGREGATE TESTS

|

TEST |

RANGE |

RESULTS VALUE |

|

Impact Value Test |

Not more than 30% |

4.31% |

|

Water Absorption Test |

Not more than 3% |

2.70% |

|

Specific Gravity Test |

2.5 to 3 |

2.69 |

|

Shape Test Flakiness Index Elongation Index |

Less than 25% Less than 15% |

17.8% 14.66% |

|

Abrasion Value Test |

Less than 30% |

17.42% |

|

Crushing Value Test |

Less than 30% |

26.11% |

|

Stripping Value of Aggregate |

Strip should not more than 5% |

2% |

|

Not exceed 5% |

1.47% |

TABLE 2.

VALUES OF BITUMEN TESTS

|

TEST |

RESULTS VALUE |

|

Penetration Test |

69mm |

|

Specific Gravity Test |

1.007 |

|

Ductility Test |

1146.6 mm |

|

Softening Point Test |

560C and 570C |

|

2250C 2300C |

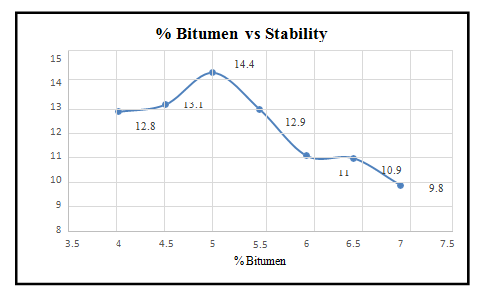

Fig. No. 1 Variation of Marshall Stability with different binder content

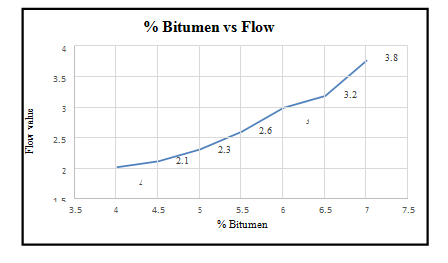

Fig. No. 2 Variation of flow with different binder content

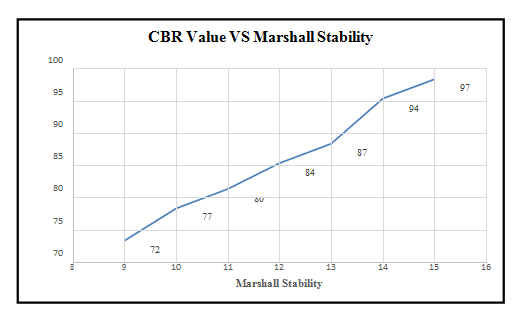

Fig. No.3 CBR Value (%) VS Marshall Stability

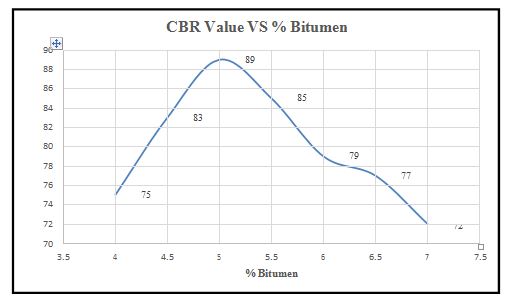

Fig. No. 4 CBR Value (%) VS Bitumen

A. Stability

The relationship between the percentage of bitumen and the stability (in kN) of a material. Initially, as the bitumen percentage increases from 4% to 5.5%, stability rises, peaking at 14.4 kN. However, further increasing the bitumen percentage beyond 5.5% leads to a decrease in stability, dropping to 9.8 kN at 7% bitumen. Thus, there is an optimal bitumen percentage for maximum stability, beyond which stability decreases.

B. Flow Value

As the bitumen content increases from 4% to 7%, the flow value also increases, indicating that higher bitumen content results in a more deformable mix. This trend is linear, suggesting a consistent increase in flow with bitumen percentage.

C. Air Voids

As the percentage of bitumen increases from 4% to 7%, the percentage of air voids decreases, starting at 7.1% and dropping to 3.8%. This indicates a negative correlation: higher bitumen content leads to fewer air voids.

D. Voids in Mineral Aggregate

As the percentage of bitumen increases from 4% to 7%, the percentage of VMA also increases, starting at 17% and rising to 20.9%. This suggests a direct positive correlation between the bitumen content and VMA.

E. Voids Filled with Bitumen

As the percentage of bitumen increases from 4% to 6%, the percentage of VFB also increases, indicating a positive correlation. Specifically, VFB rises from 58% to 83.1% as the bitumen content increases.

F. Unit Weight

As the bitumen percentage increases from 4% to 5%, the unit weight rises, peaking at 2.524. However, beyond 5%, further increases in bitumen percentage result in a decline in unit weight, dropping to 2.462 at 7% bitumen. This indicates an optimal bitumen percentage around 5% for maximum unit weight, with both lower and higher percentages leading to decreased unit weight.

As Marshall Stability increases from 9.8 to 14.4, the CBR value consistently rises from 72 to 90. This indicates that higher Marshall Stability is associated with higher CBR values.

As the bitumen percentage increases from 4% to 5%, the CBR value rises from 75 to a peak of 89. Beyond 5%, further increases in bitumen percentage result in a decline in CBR value, dropping to 72 at 7% bitumen. This indicates that the optimal bitumen content for maximum CBR value is around 5%, with both lower and higher percentages leading to reduced CBR values.

References

[1] Akhtar, M. N., Al-Shamrani, A. M., Jameel, M., Khan, N. A., Ibrahim, Z., & Akhtar, J. N. (2021). Stability and permeability characteristics of porous asphalt pavement: An experimental case study. Case Studies in Construction Materials, 15. [2] Özel, F., Deniz, M. T., & Yüce, M. ?. (2023). Evaluation of olive pomace and SBS modified bitumen to the performance characteristics. Case Studies in Construction Materials, 19. [3] Cho, Y. H., Yun, T., Kim, I. T., & Choi, N. R. (2011). The application of Recycled Concrete Aggregate (RCA) for Hot Mix Asphalt (HMA) base layer aggregate. KSCE Journal of Civil Engineering, 15(3), 473–478. [4] Ge, D., Ju, Z., Duan, D., Lyu, S., Lu, W., & Liu, C. (2023). Normalized fatigue properties of asphalt mixture at various temperatures. Journal of Road Engineering, 3(3), 279–287. [5] Julián Rivera, J., Battista, N. D., Oviedo, A., Rebollo, O. R., Zapata Ferrero, I., Fensel, E. A., Luis Delbono, H., & Martínez, A. H. (2023). Cold mix asphalt with polymeric stone for low traffic volume roads. Construction and Building Materials, 401 [6] Khan, D., Khan, R., Khan, M. T., Alam, M., & Hassan, T. (2023). Performance of hot-mix asphalt using polymer-modified bitumen and marble dust as a filler. Journal of Traffic and Transportation Engineering (English Edition), 10(3), 385–398 [7] Muniandy, R., Ismail, D. H., & Hassim, S. (2018). Performance of recycled ceramic waste as aggregates in hot mix asphalt (HMA). Journal of Material Cycles and Waste Management, 20(2), 844–849 [8] Naser, M., Abdel-Jaber, M. tasim, Al-shamayleh, R., Louzi, N., & Ibrahim, R. (2022). Evaluating the effects of using reclaimed asphalt pavement and recycled concrete aggregate on the behavior of hot mix asphalts. Transportation Engineering, 10. [9] Oreškovi?, M., Santos, J., Mladenovi?, G., & Rajakovi?-Ognjanovi?, V. (2023). The feasibility of using copper slag in asphalt mixtures for base and surface layers based on laboratory results. Construction and Building Materials, 384. [10] Sangsefidi, E., Ziari, H., & Sangsefidi, M. (2016). The effect of aggregate gradation limits consideration on performance properties and mixture design parameters of hot mix asphalt. KSCE Journal of Civil Engineering, 20(1), 385–392. [11] Tagbor, T. A., Mohammed, L., Mohammed, M., Bruce-Mensah, M. M., Tekpetey, S., Armoo, E. A., Adomah, R., Arthur, T. D., Agyenim, F. B., Amoah, J. Y., Laryea, G. N., & Serkan Kirghiz, M. (2022). The utilization of palm kernel shells and waste plastics in asphaltic mix for sustainable pavement construction. Scientific African, 16. [12] Vargas, C. A., Lu, H. R., & El Hanandeh, A. (2023). Environmental impact of pavements formulated with bitumen modified with PE pyrolytic wax: A comparative life cycle assessment study. Journal of Cleaner Production, 419.

Copyright

Copyright © 2024 More Harish Shantaram, Fulpagare Kapil Ratilal, Ratnaparkhi Bhavesh Kiran, Kadhre Pratham Bhalchandra, Prof. P. R. Badgujar, Prof. S. Y. Sonawane, Prof. J. P. Bhadane, Prof. N. R. Borase. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET65067

Publish Date : 2024-11-07

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online